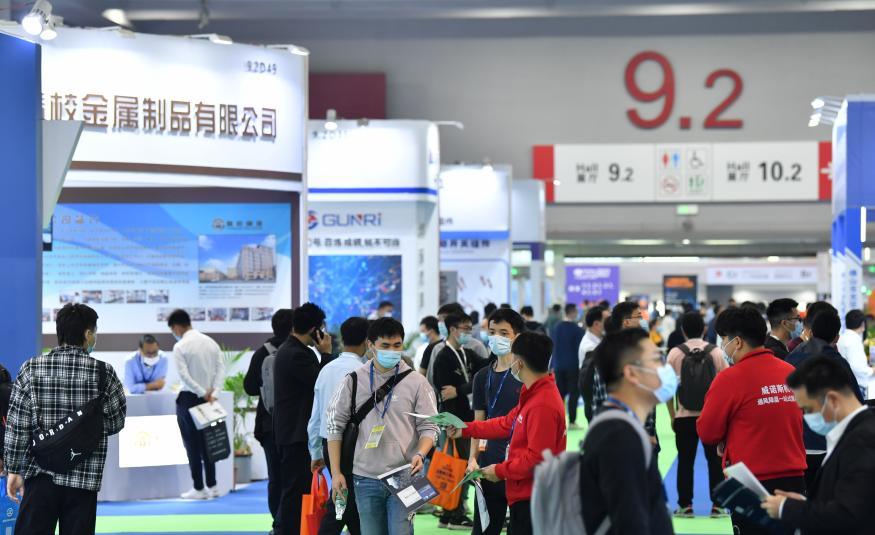

The 13th edition of SPS- Industrial Automation Fair (SIAF) Guangzhou and Asiamold were hosted, 3-5 March, at the China Import and Export Fair Complex. The two fairs attracted 408 exhibitors to showcase their latest innovations and smart manufacturing solutions, attracting 23,825 visitors.

Both under the smart manufacturing cluster, the fairs aim to serve as a platform for the adoption of advanced, sustainable, efficient and high-precision manufacturing technologies within the Chinese domestic market.

Hubert Duh, chairman of Guangzhou Guangya Messe Frankfurt, the event organisers of the fairs, stated: “China’s market for digitised technologies, extending to the smart manufacturing sector, is growing at a rapid rate. Advancements in sensors, machine vision, robotics, additive manufacturing and mould-making technologies, together with the adoption of industrial information technologies by manufacturers within the region, will inject a whole host of opportunities for solution providers in the industry.”

SIAF Guangzhou and Asiamold offered concurrent programmes for exchanging market intelligence and future industry developments, led by industry experts representing firms in China. The topics coincided with a number of the latest national policies and initiatives on raising domestic production and technological innovation standards, including sustainable manufacturing, 5G, digital factories, digital transformation, data transactions, 3D printing technologies and mould-making technology.

Exhibitor Norman Ye, deputy general of sales department at Dongguan Fine Alignment Metal Products, said: “This is our first time participating at Asiamold and despite the ongoing global healthcare situation, it did not slow down buyers from sourcing our moulding products. We are extremely pleased with the 2022 fair and are delighted to report that the event met our exhibiting expectations.”

Buyer Yi Liu, visual application department manager at Guangzhou Risong Hokuto Automotive, added: “We have been attending SIAF Guangzhou for five years and our company is mainly a system integrator of high-end intelligent manufacturing, specifically for the automotive industry. This year, we came purposely to source for the latest machine vision technologies and products and have established brief communications with a few well-known suppliers including Cognex and Aqrose Technology.

“With the advancement in machine vision technology, the combination of 3D machine vision, AI learning for quality control and the latest IoT technologies are some of the most important development focuses for reassuring production efficiency and quality. Sustainability is very important for our organisation, and we prefer to source for products that are energy efficient,” Liu concluded.